We’re a fully-integrated, precision manufacturer of automated and robotically-controlled tube bending equipment. Our state-of-the-art facilities are designed to produce solutions that spur innovation and accommodate our clients’ needs.

Learn MoreWe’re committed to providing you with the highest level of service, so you’ll always be

happy that you chose us.

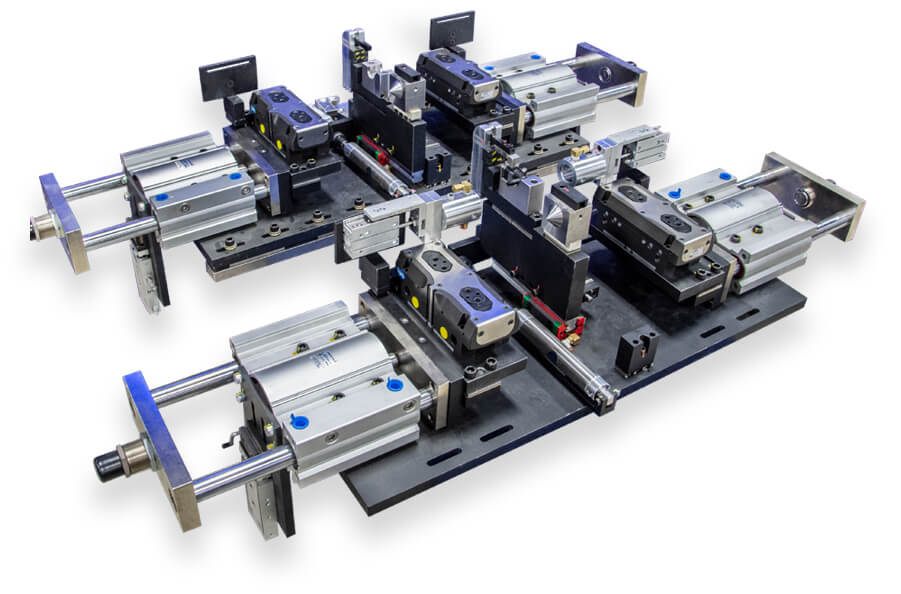

Fixture Building is a trade that most people aren't familiar with. Here at MW Solutions

LLC, we promise to never unfairly take advantage of someone who needs our services.

We pride ourselves on our honesty and integrity and we firmly believe that you'll see the

difference when you choose our company. We've also been family- owned and operated

from the start.

We may not be related, but you’ll feel like we’re family.

Learn More

MW Solutions designs equipment to provide the highest quality throughput for each product. Our design engineers work closely with each client to provide the best in 3D design for any automation

challenge. Through the use of such programs as Mastercam and Inventor, our customers can be confident the equipment they receive uses the most advanced technology available.

Our team of engineers is highly qualified and possesses the experience and knowledge needed to deliver. MW Solutions is fully commited to ensuring every customer’s requirements are met with

100% satisfaction.

MW Solutions builds fully automated nylon tube bending equipment. Our Nylon tube benders are built using the latest and most up to date Technology. We utilize a thermal conduction style of heating and an infrared style for cooling the parts. Our machines are fully automated from start to finish with reject system to ensure that only good parts are accessible by the operator.

Our Nylon tube bending machines have a multitude of options to fit your every need. Our sales and engineering team will work with you every step of the way to ensure the correct type of process that fits your needs.

Learn More

MW Solutions has years of custom tube bending and design experience, which means your custom projects will be built with the highest quality. All design and custom machining is handled in-house. With our ISO 9001:2015 certification we follow the highest industry quality standards when designing and building to your custom specifications.

MW Solutions offers a wide range of possibilities for creating custom tube configurations to suit your needs. Our experience with roll dies and resistance bending allow for tubing materials of up to 2 inches in outside diameter (OD) and wall thicknesses from 0.01- 0.125 inches. With capabilities of bend Steel, Stainless Steel, Copper, and Other various materials.

Learn More

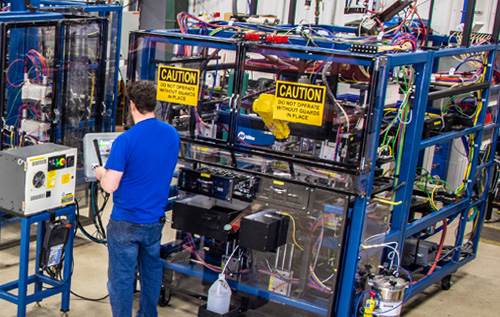

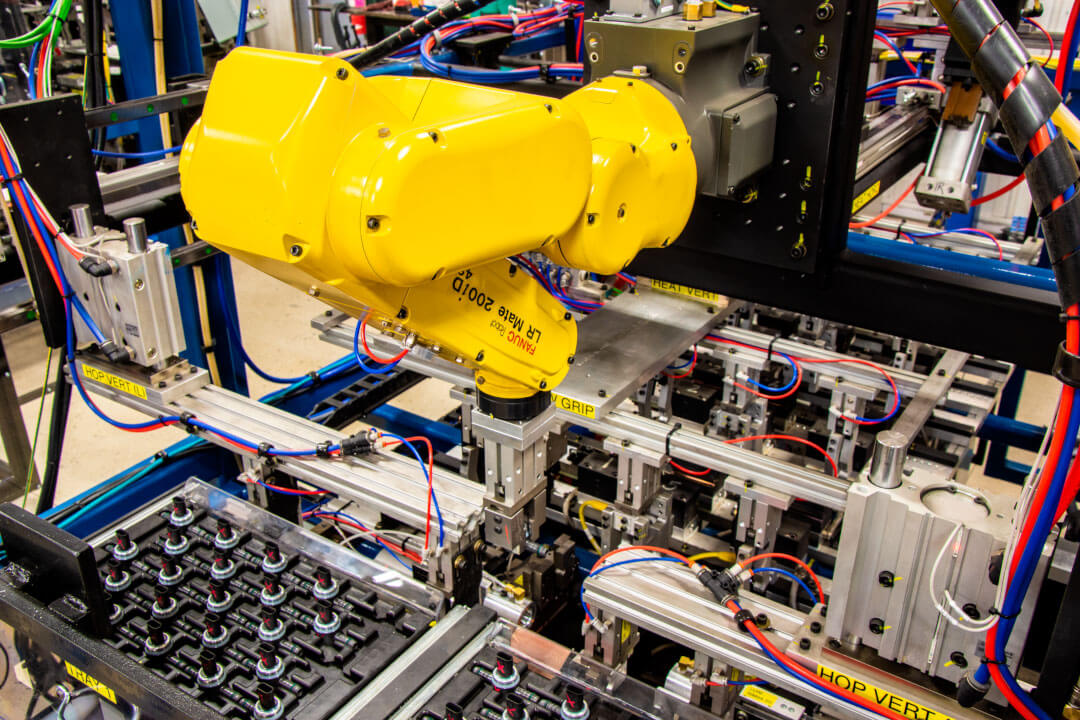

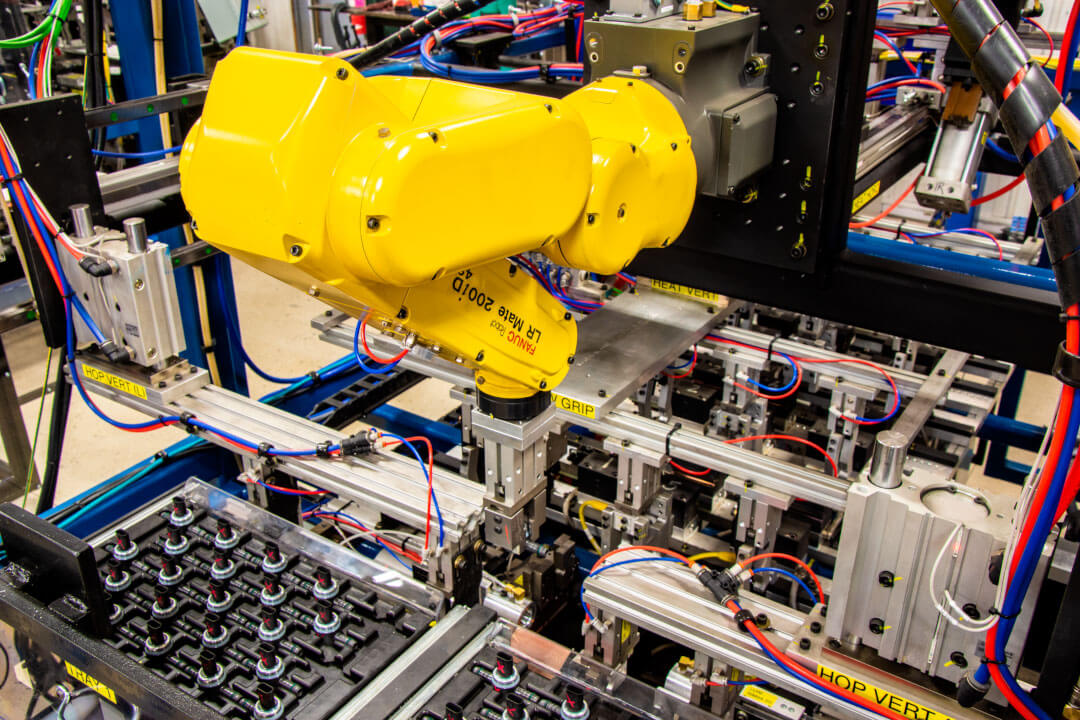

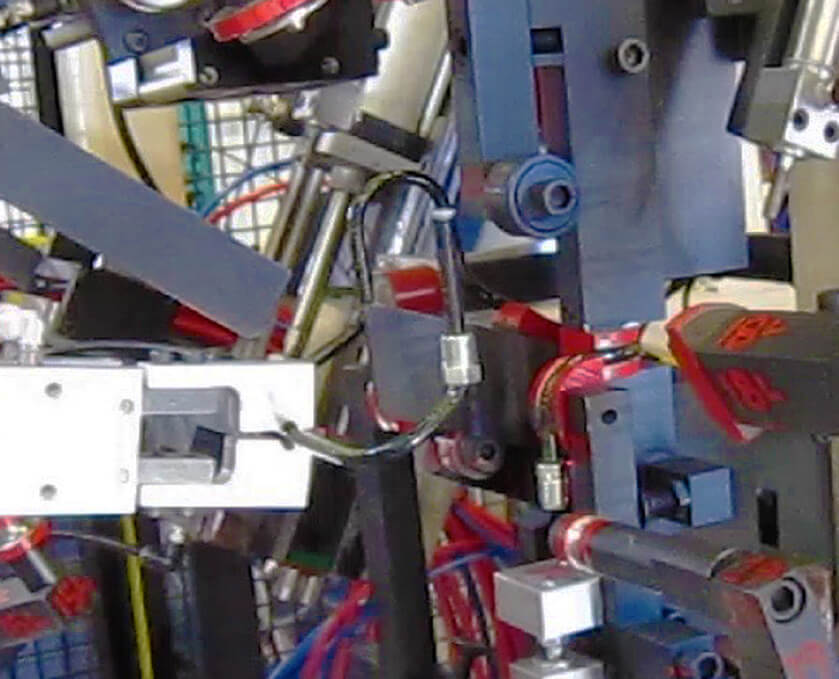

MW Solutions is an integrated design, fabrication and installation of multiple brands and styles of robotic systems. MW Solutions serves the automotive, aerospace, medical, electrical and consumer industries.

We understand how daunting acquiring and maintain the labor force can be. With the integration of robotic systems it can help lighten the demand and increase productivity. New style collaborative styles have the ability to work in conjunction with personal.

At MW Solutions, we don't just sell robots; we sell customized solutions that fulfil your specifications. We design, engineer and machine every component of the robotic system. We thoroughly run and debug the entire system to your desired specifications, ensuring you have a complete and functional system.

Learn More

At MW Solutions, our fully-equipped machine shop provides CNC machining services making metal and plastic prototypes and production parts for a wide range of customers. We provide quick turnaround while adhering to the strictest quality standards. Every part is carefully gauged for accuracy.

We machine production parts, provide assembly, and offer various secondary operations, such as coating and surface treatments. Our 3D engineering, utilizing Mastercam and Inventor software, brings your concept to life.